Curtain Coating

Curtain coating formulations custom engineered to improve your production process.

Partner with RDC Coatings to develop custom solutions that enhance the speed and throughput of your curtain coating process.

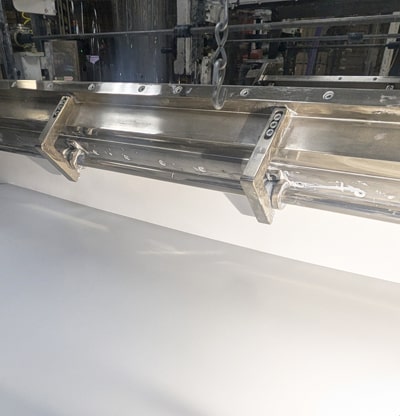

Curtain coating application is a highly efficient technique that creates a continuous flow — or curtain — of coating that falls onto a moving substrate. Passing through the curtain at a steady speed creates a consistent, uniform coating on the substrate. Coating thickness is controlled by adjusting the curtain’s flow rate and the speed of the substrate. The coating is then solidified via an ultraviolet (UV), Excimer UV, or electron beam (EB) energy curing process.

Curtain coating is often used in furniture manufacturing. It is ideal for finishing wood, metal, and other large, flat, rigid substrates where a smooth, blemish-free surface is required. Partnering with RDC Coatings for custom engineered, energy cured curtain coating formulations results in finishes that set faster. That translates directly into higher production speeds and greater throughput.

RDC’s environmentally friendly 100% solids UV and EB curtain coatings and finishes are available as both clear and opaque top coats, as well as in “wet-on-wet” base coat / clear curtain coating systems. They can be specified with pigments and in varying degrees of gloss. Providing nearly 100% transfer efficiency, RDC’s sustainable curtain coatings are engineered for high durability, exceptional adhesion, and enhanced resistance to abrasions, scratches, chemicals, and water.

Benefits of your RDC Coatings’ formulations for curtain coating.

Make RDC Coatings your resource for curtain coating formulations that enhance your application process. Your custom engineered finishes will match the parameters of your production line, application and curing equipment, environment, and product.

Curtain Coatings That Improve Your Production Process

For operations assessing an existing curtain coating formula, looking to add new finishes, or developing a new manufacturing line, RDC supports your coating with customer-focused expertise. Included are on-site process audits that give RDC insight into your coating line and finished products. Based on that information, RDC’s engineers custom formulate your curtain coating and verify its performance in state-of-the-art testing labs. Further, RDC offers process management and technical support services.

Curtain Coating Formulations Tailored to Your Application Equipment

RDC custom engineers your curtain coating solution to enhance the operation of your application equipment. For smooth, uniform flow, each coating’s rheology is specifically optimized for your machines. Additionally, your curtain coating formulation can be provided in containers sized to meet your operation’s needs, increasing your processes’ efficiency and productivity.

Curtain Coatings Customized to Enhance Your Curing Process

The chemistry of your ultraviolet (UV), Excimer UV, electron beam (EB), or water-based coatings delivers fast curing, uniform finishes that minimize drying time. For operations using a UV curing process, RDC’s curtain coatings are designed to successfully cure under a wide range of operating conditions. Whether the bulbs are new or approaching the end of their useful life, your RDC curtain coating will still deliver exceptional lot-to-lot consistency.

Curtain Coatings That Deliver an Even Finish in Variable Environments

RDC Coatings understands that very few manufacturing facilities are climate controlled. Therefore, your curtain coating’s formulation is built to deliver consistent performance year-round, in high or low temperatures and humidities.

Curtain Coating Chemistries Designed to Meet Your Product Specifications

Each coating RDC formulates is customized to match your specific product requirements.This includes chemical resistance, scratch and abrasion resistance, weatherability, gloss, adhesion, and more.

Your partner for sustainable, compliant energy-cured finishes

All RDC UV curable finishes are environmentally friendly and comply with globally accepted safety and sustainability standards, including…

- Low or No Volatile Organic Compounds (Low-VOC/Zero-VOC)

- California Air Resources Board (CARB) Compliant

- American Innovation and Manufacturing (AIM) Act Compliant

- Meets or exceeds American National Standards Institute (ANSI), Kitchen Cabinet Manufacturers Association (KCMA), and Scientific Equipment and Furniture Association (SEFA) Testing Requirements

How Can RDC Coatings Help You?

Manufacturers in multiple industries apply RDC Coatings’ custom formulations to a wide variety of materials and products. Leverage RDC Coatings’ 35-plus years of experience in engineering, developing, and manufacturing custom, energy-cured coatings to address your unique needs.