Coatings for Plastic

Energy-curable plastic coatings that deliver enhanced durability across a variety of products.

RDC Coatings supplies sustainable coatings for plastic films, flooring, entertainment media, and more.

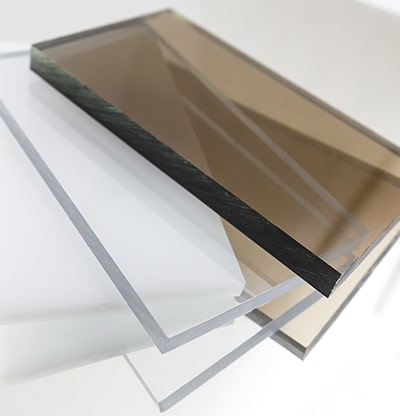

Plastics operations applying coatings to products such as flooring, CDs and DVDs, plastic films, engage RDC Coatings to develop sustainable, energy-cured finishes. Custom formulated, environmentally friendly ultraviolet (UV) curable coatings, electron beam (EB) curable coatings, Excimer UV curable coatings, and water-based (WB) finishes from RDC are applied to a variety of different types of plastic materials — enhancing durability, scratch resistance, and appearance. Let RDC engineer your optimal UV and EB curable plastic coatings, specially formulated for acrylic, composite, polycarbonate, polypropylene, polystyrene, hybrids, and more.

UV and EB Curable Plastic Coatings

Utilizing the same application methods as conventional plastic coating processes, RDC Coatings’ UV and EB finishes provide excellent scratch resistance. The custom-engineered plastic coatings also resist solvents, stains, and scratches. Available in a variety of glosses and textures, these plastic coatings are used in:

- Resilient flooring applications to create a maintenance-free plastic flooring material.

- Printing of plastic or laminated films used to wrap flooring transition moldings to match engineered flooring.

- Finishing polycarbonate materials, such as CDs and DVDs, with clear or opaque coatings to enhance scratch resistance.

Benefits of RDC’s Coatings for Plastics to Optimize Manufacturing Efficiency

Custom-engineered plastic coatings for every manufacturer's finishing line.

All of RDC’s energy-cured finishes can be applied to plastic products with roll coating, spray coating, curtain coating, vacuum coating, or dip coating. RDC Coatings’ UV and EB curable plastic coatings and finishes are formulated to produce excellent transfer efficiency and are designed for seamless integration into existing manufacturing lines, offering high-performance finishes with excellent transfer efficiency.

Durability and Protection with Advanced Plastic Coatings

For industries requiring long-lasting plastic finishes, RDC offers custom-made curable plastic coatings engineered for superior scratch, stain, and solvent resistance. Our coatings extend product life by enhancing durability for flooring, entertainment media, and plastic films, reducing the need for replacements and warranty claims.

EB and UV Coatings for Polycarbonate and Other Plastic Substrates

Our UV coating for polycarbonate and other plastic materials ensures enhanced protection and surface durability. Whether applied to CDs, DVDs, or polycarbonate sheets, these coatings improve scratch resistance while maintaining optical clarity.

Custom-Formulated Curable Plastic Coatings to Meet Your Manufacturing Needs

At RDC Coatings, we understand that every manufacturer is different, and we prioritize developing curing plastic coatings tailored to your specific application methods, durability standards, and aesthetic preferences. Whether you need high-gloss, matte, or textured finishes, our coatings are designed for superior performance in roll coating, spray coating, curtain coating, vacuum coating, or dip coating applications.

Sustainable Coating Solutions to Support Eco-Friendly Manufacturers

Manufacturers are prioritizing sustainability without sacrificing quality. RDC Coatings provides UV-curable plastic coatings, EB-curable plastic coatings, and water-based finishes that reduce emissions and energy consumption. These environmentally responsible coatings help companies meet regulations while delivering durable, high-quality products.

For industrial wood floor coatings and any other industrial floor coatings, contact us today.

Your partner for sustainable, compliant energy-cured finishes

All RDC UV curable finishes are environmentally friendly and comply with globally accepted safety and sustainability standards, including…

- Low or No Volatile Organic Compounds (Low-VOC/Zero-VOC)

- California Air Resources Board (CARB) Compliant

- American Innovation and Manufacturing (AIM) Act Compliant

- Meets or exceeds American National Standards Institute (ANSI), Kitchen Cabinet Manufacturers Association (KCMA), and Scientific Equipment and Furniture Association (SEFA) Testing Requirements

How can RDC Coatings help you?

Manufacturers in multiple industries apply RDC Coatings’ custom formulations to a wide variety of materials and products. Leverage RDC Coatings’ 35-plus years of experience in engineering, developing, and manufacturing custom, energy-cured coatings to address your unique needs.